These are our original wedding rings when they were new in January, 2004. We used the one on the left, mine, to create two new rings while we were here in Rishikesh. (Jan 2004)

Back to top

Our goldsmith, Kalu, sits in his tiny hall of an office next to a jewelry store. We sat with him half in the hot sun most of four hours as he made the two rings. The only time we were away was when we visited other shops as indicated below. (28 Mar 2017)

Back to top

Kalu took us to his brother's smelting shop where we first melted the ring. Here it is already well on its way to liquid form as it sits a crucible in fanned charcoal. (28 Mar 2017)

Back to top

Now to separate the gold from the alloy metals the smelter adds some acid. I think it was nitric acid. (28 Mar 2017)

Back to top

That mixture goes into the oven and stews a while giving off a vile smelling smoke. (28 Mar 2017)

Back to top

After two or three rounds of the previous step, he empties the result into this bowl. It looks like a powder! Where was the gold? (28 Mar 2017)

Back to top

Something more is added and back in the fire it goes. (28 Mar 2017)

Back to top

That is melted together. Here he pulls the pure gold out glowing hot. (28 Mar 2017)

Back to top

Now its weighed to make sure nothing has disappeared. 13.43 grams, the calculated amount. (28 Mar 2017)

Back to top

Petra is holding my transformed ring, a pure gold blob. [maybe it is already alloyed here—I do not remember for sure.](28 Mar 2017)

Back to top

In a step not documented they add silver and copper to harden it and bring it .8 purity. It is melted again and poured into a form. Here someone holds the alloyed bar. (28 Mar 2017)

Back to top

Kalu stands with his brother, the smelter, who is holding the gold ready to be made into two rings. (28 Mar 2017)

Back to top

Kalu takes us back to his workplace and begins to pound the gold into the rings. (28 Mar 2017)

Kalu heats the gold many times as he works on the ring. He blows through a tube over the fire to get a very hot flame. Here he is heating the initial ingot. (28 Mar 2017)

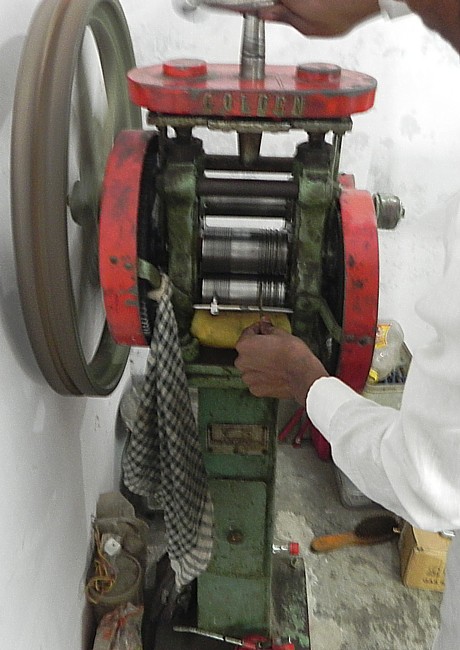

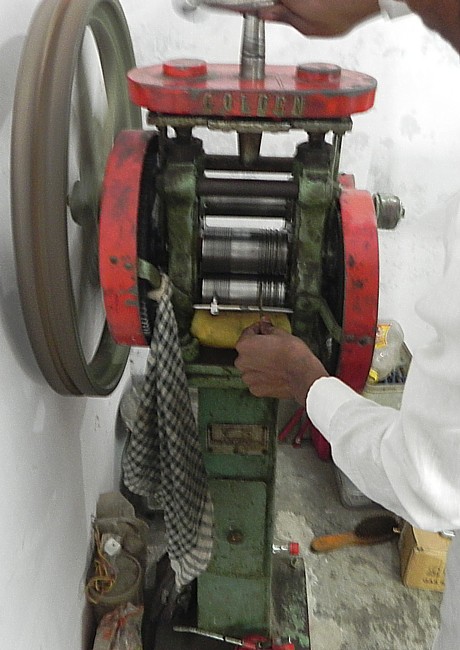

We then go to a neighboring jewelry store where they have a shop and a rolling mill. Here we mill the ingot into a fairly uniform flat bar ready now to hammered into the ring. (28 Mar 2017)

Before beginning to work with the ring after coming back from the milling maching, Kalu once again heats up the bar, now longer and flatter. (28 Mar 2017)

Movie clip: Forming the ring. The Notice how he holds the from with his talented feet. [The movie in 14 megabits long. It may take a while to load.]. (28 Mar 2017)

Back to top

Movie clip: Fitting the ring. Here Kalu slowly changes the circumference of the ring to form it to the finger size. [The movie in 17 megabits long. It may take a while to load.] (28 Mar 2017)

Back to top

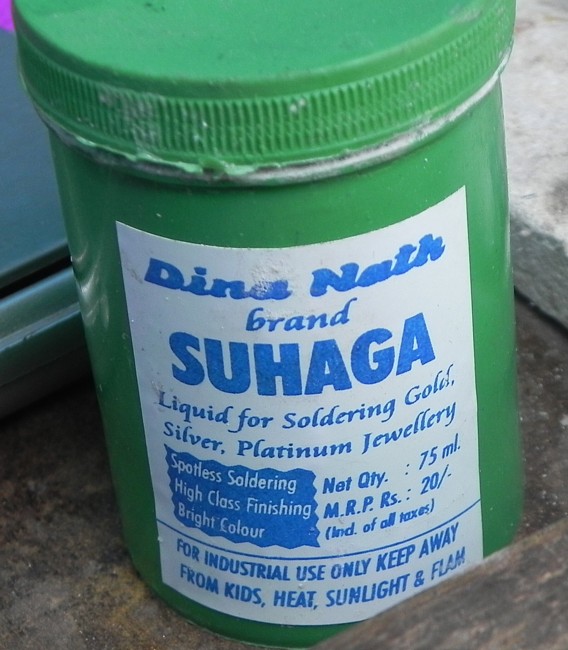

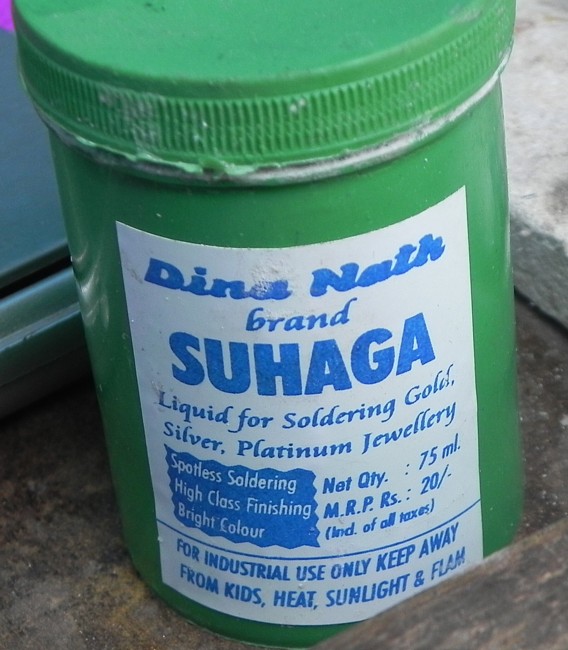

Now Kalu uses this solder flux and tiny pieces of gold along with his burner to solder the ends of the ring together to make the completed round ring. (28 Mar 2017)

Back to top

At this point, Kalu is finished making my ring. During the process he has chopped up the remaining gold into several little pieces. This along with tiny filings from the final work on my ring will now be remelted to make Petra's ring. (28 Mar 2017)

Back to top

Using the burner and the blow pipe Kalu melts the gold into a ball. (28 Mar 2017)

Back to top

The ball of gold. (28 Mar 2017)

Back to top

the process started over for the second ring. The metal was milled and pounded and now sits on the scale with the first new ring. (28 Mar 2017)

Back to top

Kalu begins to pound out the rolled ingot. (28 Mar 2017)

Back to top

We were watching the ring making progress from our seats almost on the edge of the road. People and scooters were continually passing. The noise of the city was with us. (28 Mar 2017)

Back to top

Before closing and soldering the ring together, here Kalu punches the fineness on the ring interior. (28 Mar 2017)

Back to top

With the second ring made, it was time to polish both. Kalu took us up three dark flights of steps to a cubby-hole of a room on the roof of a nearby store. (28 Mar 2017)

Back to top

The polisher first cleaned the rings, boiling them in acid. No one could stand inside the room. I got a whiff of the fumes and came close to choking. (28 Mar 2017)

Back to top

Then he polished them at this closed-in polisher. (28 Mar 2017)

Back to top

That day was New Year's Day 2074 on the Vickrama Samvat calendar system used in this part of India. This calendar started to count in 58 BC of our calendar. It was also new moon and the beginning of the nine-day feast of the Divine mother—an auspicious day indeed.(28 Mar 2017)

Back to top

Kalu and the polisher hold the finished rings for me to photograph them. (28 Mar 2017)

Back to top

And this is their second picture sitting together on blue paper on Kalu's work table, the work is done for now. Petra's proved to be somewhat mal-formed so he had to remake it the next day. It was no problem. We really enjoyed watching the process from beginning to end. We never thought it was possible to get such a complex task done with so much dispatch in India. Thanks, Kalu. (28 Mar 2017)

Back to top

Back to top